Oh! So the whole point of that little lecture on DC motor control was to point out this:

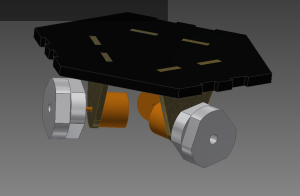

This sexy AutoDesk Inventor 3D simulation has motors bolted via the static face to the chassis, with a minimum of distance between the support and the wheel. Because that’s optimal, and because that’s normal for brushed motors. The motors have only just arrived, the simulation only has 4 parts *and it is already wrong* because it makes assumptions.

Which is not a big deal. But it’s a warning. “It worked in CAD” is an insidious trap for young players – the question is, when it fails to work in real life, do you change the part to match the drawing, or the drawing to match the part?