Holidays, thank fuck. Terrible exams, dubious results. So now I get to make things.

Machine shop

I recently spent a week or so at Tharwa Valley Forge, doing a couple of courses. “One dayu, One Knife”, and “Blacksmithing Foundations”. Both were amazing, and I wish I’d done them years ago! The One Day, One Knife (with stock removal, rather than forging) certainly lived up to expectations – it was the perfect mix of doing the hard yards and learning the basic skills of grinding and shaping and heat treatment, with a little help from the instructor just to finesse the final shape. Continue Reading

My current project is a reaction wheel inverted pendulum – a single DOF version of this: https://www.youtube.com/watch?v=woCdjbsjbPg&t=4s

To that end, I’ve been milling and drilling and tapping, oh my.

For a man who buys machine screws by the hundred, it’s surprising how often I don’t have the right machine screws. Nonetheless. One of those is a motor mount, and one will form the back side of a clamp. The idea is that it’s adjustable along the length of the stick, otherwise I have to do math first. This way I can ballpark the wheel mass, and then tweak it physically.

Motor mounted:

Turns out, of course, the mounting screws for these aren’t in a square. That’s actually pretty common for these – so common I had an adapter plate lying around. Since it mattered to me that the holes be pretty precise, I used one to make up a jig. I don’t care so much about the location of the motor in terms of centred and plumb – it’s constrained pretty well by the slots. But in relation to each other I want the holes spot on. So, time to make a jig.

Drilling the top hole allowed me to put in one screw, which then holds the whole thing in place while I drill the rest.

The first screw, of course, went in fine. The second had that moment of joy swivelling the motor into place as the screw hole swung under the screw and it clicked into place. With those two in, the last two went in perfectly first time. I love it when a plan comes together. The motor itself is within half a mm of centre – not bad for a freehand jig. It’ll do fine.

And that’s the idea. Screws I’m currently missing are countersunk M3, so I can actually mount the motor and still put the clamp on the mast, and M5x14mm. I have M5x12, which are just long enough, except for one corner. I got carried away in the initial assembly and cranked a little too hard with only one screw, stripping the top thread out of the hole. So I grabbed an M5x16, which is too long. By about 2mm. And apparently I have no 14mm.

Still, at some point I need to think about mounting electronics, so the 16 may give me space to add a 2mm plate for the ESC and battery. And so it goes ….

Had a bunch of stuff going on the last year, nothing to say about it. But now, I’m finally back in the garage, and especially down in the machine shop. One project for this year will be an inverted pendulum – I’m doing an internship at the Australian Synchrotron, which is interesting, but has less math and theory than I was expecting, and I’m in danger of getting rusty. So I figure I can design and build a reaction wheel inverted pendulum – a single DOF version of this: https://www.youtube.com/watch?v=woCdjbsjbPg

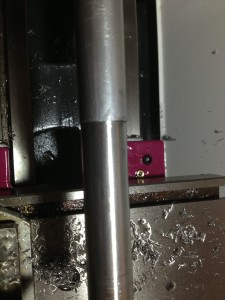

So, finally, got the mill running, and made some aluminium chips:

Somewhere inside all that is a slide plate that will have a motor mounted to it:

The fit is pretty good:

It’ll end up a bit like this, but with a big spinning motor on it:

I had the same discovery that I keep making in the machine shop – everything can run faster 🙂 Both steel and aluminium now, I’ve made some cuts, they seemed a bit painful, I did more research and discovered I should be running the cutter about twice as fast. Then it gets a lot less painful 🙂 So I’ll bear that in mind when I make the actual reaction wheel …

In the background, I’ve been cleaning up an old dial gauge:

It hasn’t been treated well, and it’s a bit sticky. The internet (actually, Tom Lipton of OxToolCo) recommends light fluid for cleaning it up:

Initial results are promising – it gets a bit sticky again the next day, but it’s getting there – snaps back better now than it did.

It’s been a while. Robot hands and 3d printers and lathes, oh my.

Counting backwards, this time!

Monday:

Hot dusty dirty day of drilling holes in concrete. They always need to be a little deeper than you think. 6 holes for the lathe, 2 for the mill. Other than that, not much happened on Monday.

Tuesday:

Nerds came over, helped me finish up the tools, spent a lot of time helping me shop for lubrication. With the following result:

Very pleased! Robot axles ahoy! To Star Wars afterwards, with even more nerds. It still doesn’t suck.

Wednesday:

Shopping for bolts to bolt the mill down. Small bolt/hardware stores with $25 EFTPOS minimums are dangerous, it cost me $50 to make up that $25. Still:

Brass machines beautifully. Did I mention I bought a lathe?